Annealed Glass

Last Updated: July 31, 2024

Share Article

Annealed Glass

Annealed Glass

The annealing process involves slowly cooling molten glass in a controlled environment to relieve internal stresses that could cause the glass to break or shatter easily. This process gives the glass its low surface stress and allows it to be cut, shaped, and processed further without the risk of breakage.

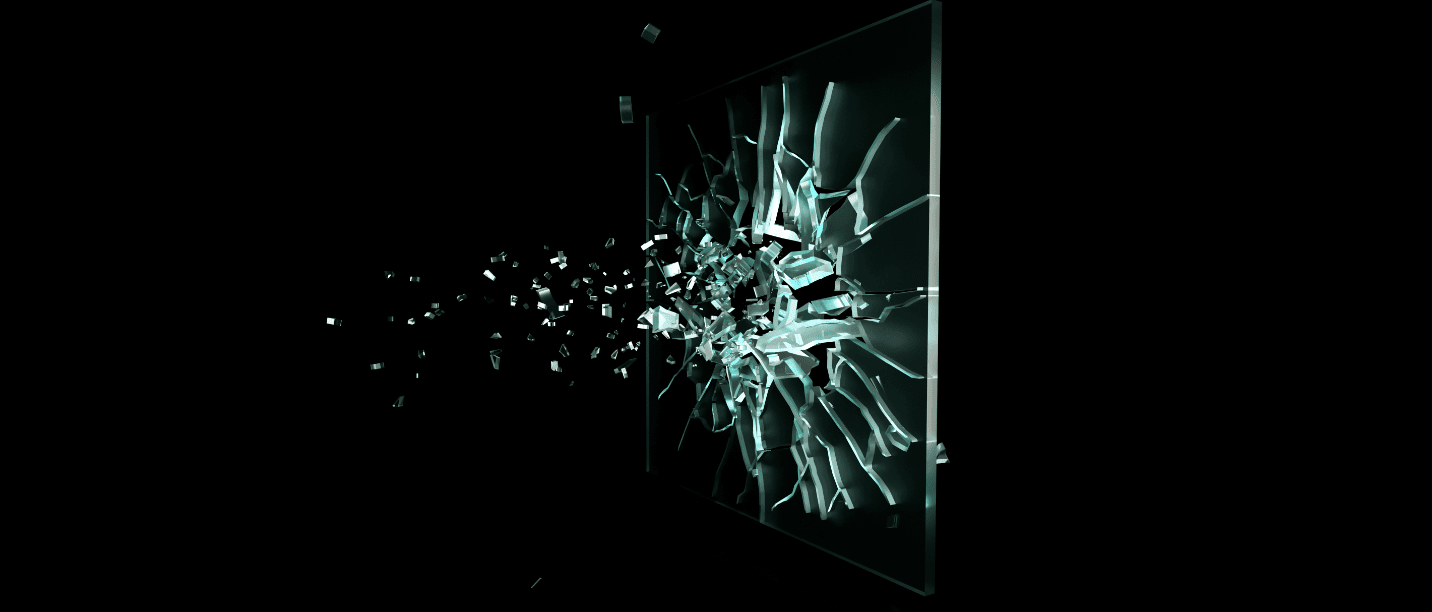

In comparison to tempered or heat-strengthened glass, annealed glass is less strong and more susceptible to breakage upon impact. When annealed glass breaks, it produces sharp, irregular shards, which can pose a risk of injury. As a result, annealed glass is not considered safety glass and is not typically used in applications where impact resistance is necessary, or where broken glass could pose a safety hazard.

Figure: Annealed glass breakage pattern

Annealed glass serves as the base material for many other glass products, such as tempered, laminated, and LoĒ coated glass. It can be cut and shaped easily, making it suitable for various applications. However, because of its lower strength and lack of safety features, annealed glass is not recommended for use in high-impact or safety-critical applications.

More:

Related Glossary Entries:

CONTINUE READING