IQ - Tempered Glass

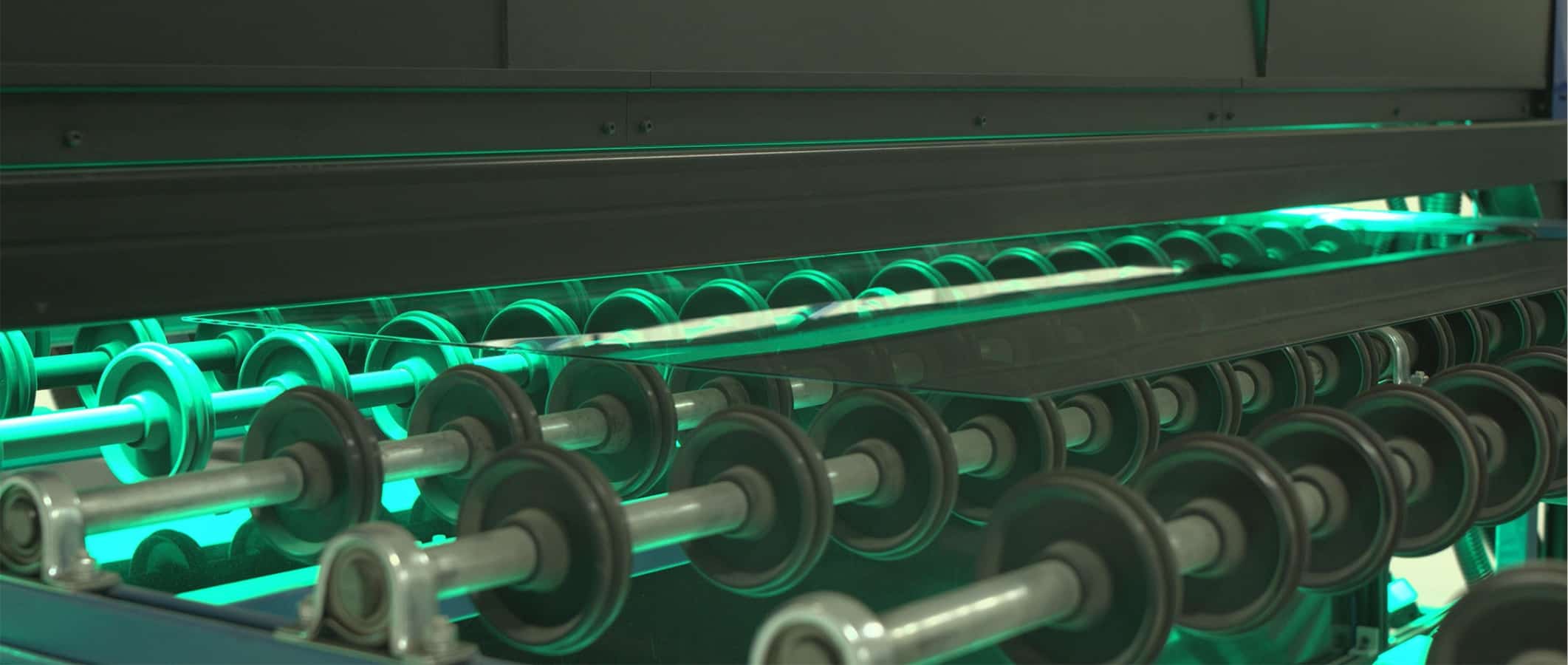

IQ Systems for Tempered Glass

Clean Start: Glass is washed prior to tempering. Tempering furnace washers feature a unique water stream particle size counter that can detect minute particles and quantifies them.

Hawkeye Camera: This high-resolution, high-speed camera is used to detect scratches, coating faults and debris on the surface.

Tempered Distortion: Competitive inspection systems read the peaks and valleys that develop as part of the tempering process but they report only an average. And not all lites are measured. Our state-of-the-art camera system measures the entire glass, focusing on a series of circles (similar to pixels). The results represent what the human eye sees.

Our state-of-the-art camera system measures glass defects.

Tempered Glass Orientation: This camera system measures the lites, matches them against the production schedule and assigns identification to our operators. This is used in packaging to prevent and eliminate confusion and mistakes.

Defect Detection: The system accurately characterizes defects by size and sorts them according to our specifications. This prevents defective glass from proceeding to high value operation.

Tempered Conformance: All Cardinal tempering facilities equip a photo elastic stress measuring system that identifies areas of non-uniform stress in the glass. Inadequate tempering is highlighted. The system stops unqualified glass products to leave our facility. Furthermore, it allows us to reconfigure procedures as necessary to obtain better heating and quenching. In return, our customers receive high quality tempered glass every time. .